Polymer Metal Oxide Surge Arrester

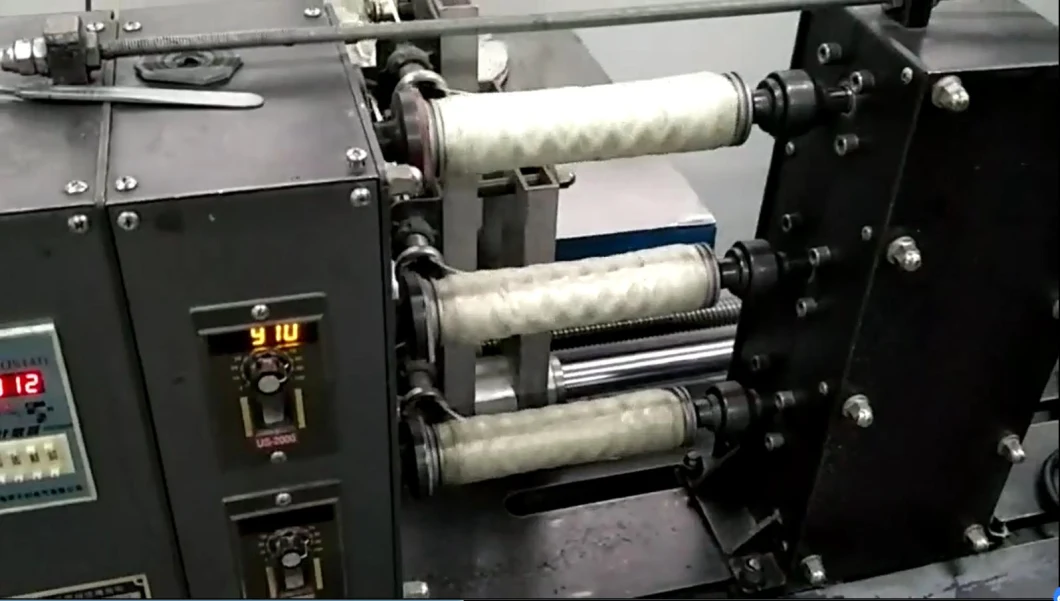

Description: The arrester produced by our company mainly adopts weftless mesh automatic winding process for core forming;

Basic Info

| Model NO. | YH10W-30/90 |

| Classification | Organic Insulating Material |

| Certification | ISO9001 |

| Color | Dark Geen |

| Brand | Wishpower |

| Transport Package | Create and Pallet |

| Specification | The packaging details ss order q′ty |

| Trademark | Wishpower |

| Origin | Xi′an, China |

| HS Code | 8546900000 |

| Production Capacity | 750000 Tons Per Year |

Product Description

Description:The arrester produced by our company mainly adopts weftless mesh automatic winding process for core forming, and the silicone rubber umbrella skirt sheath adopts integral injection molding.

Application: Composite Metal Oxide Arrester

Features:

1.Safe and reliable pressure release capabilityThe surge arrester produced by Wishpower has a unique pressure release structure. The composite wrap is wound close to the side of the resistor through a special winding process. The air gap between the resistor sheet and the no-weft tape is eliminated on the one hand, the multiple pressure release points are formed on the other hand, so that the surge arrester has a safe and reliable pressure release capability, the surge arrester can safely release the internal pressure in any accident and failure situation without causing the effect of expanding the accident.

2. High mechanical strength

The composite wrap is a semi-dry prepreg tape made of treated alkali-free glass fiber impregnated with thermosetting resin. Combined with the lay-up design theory, the winding parameters are customized to make the tape follow a certain angle and speed. It is wound on the surface of the resistance sheet and is in close contact with the resistance sheet to ensure that the wound core has high mechanical strength.

3.Reliable sealing performance

It adopts the unique sealing design structure of wrapping on the surface of the resistance sheet and the end fittings to ensure the reliable sealing performance of the arrester in the normal life period.

4.Small partial discharge

The automatic winding process of the wrap is adopted, which avoids the generation of gaps between the layers of the weft-free tape caused by human operation. At the same time, the weft-free tape is closely attached to the surface of the resistor. After the winding is completed, the core is placed in an automatic control oven for the second drying and curing, in the constant hot air circulation, the air between the fiber gaps is released to reduce the partial discharge of the product.

5.High cost-effective

Compared with other materials (glass fiber winding tube, Dureton, etc.), the composite wrap type used in the surge arrester of has higher performance and lower price. The use of automatic winding process improves the stability of product, and makes the production efficiency higher at the same time, so the this structure of surge arrester has a higher cost performance.

6.The external insulation silicone rubber(Independent research formula)

We have done a lot of optimization and improving work on the outer insulating shed and housing of the composite surge arrester, also used it in production.

Production:

Testing:

Packacing:

Certification:

You may also like

Send inquiry

Send now